Precision Injection Molding: The Key to Successful Manufacturing

In the highly competitive landscape of modern manufacturing, companies are continually seeking ways to enhance efficiency, minimize waste, and deliver high-quality products to their customers. One of the most effective methods to achieve these goals is through precision injection molding. This advanced technique has revolutionized the way products are designed and produced, making it a cornerstone for businesses, particularly in the realm of metal fabricators.

Understanding Precision Injection Molding

Precision injection molding is a manufacturing process used for producing parts by injecting molten material into a mold. The material is allowed to cool and solidify, taking the shape of the mold cavity. This method is primarily utilized for thermoplastics, but can also be adapted for metals and other composite materials, making it highly versatile.

The Process of Precision Injection Molding

The process flows through several well-defined stages:

- Material Selection: The first step involves selecting the appropriate material based on the product requirements. This could range from plastics to metals, depending on application needs.

- Designing the Mold: A precise mold must be designed to match the specifications of the final product, taking into consideration factors such as shrinkage, cooling time, and the chosen material's characteristics.

- Injection: The molten material is injected into the mold under high pressure, ensuring that it fills every nook and cranny, thus producing a part that adheres to the desired design.

- Cooling: The injected material must be allowed to cool appropriately, ensuring that it holds the shape of the mold once solidified.

- Demolding: Once cooled, the mold is opened, and the part is ejected, ready for inspection and further processing if necessary.

Advantages of Precision Injection Molding

There are numerous advantages to utilizing precision injection molding in manufacturing, particularly for businesses involved in metal fabrication. Here are some key benefits:

- High Precision and Tolerance: This method allows for intricate designs and precise tolerances, making it ideal for components that require high levels of detail.

- Efficiency: The process is highly efficient, enabling high production rates with minimal waste, which subsequently translates into cost savings.

- Versatility: The capability to use various materials, including metals, plastics, and composites, allows for wide-ranging applications across different industries.

- Reduced Lead Times: Due to the speed at which injection molding can produce parts, businesses can drastically reduce lead times, enhancing their ability to meet market demands quickly.

- Consistency: Because the process is automated and highly controlled, there is a consistent quality in the parts produced, reducing defects and the need for rework.

Applications of Precision Injection Molding

Precision injection molding is widely utilized across various industries, including:

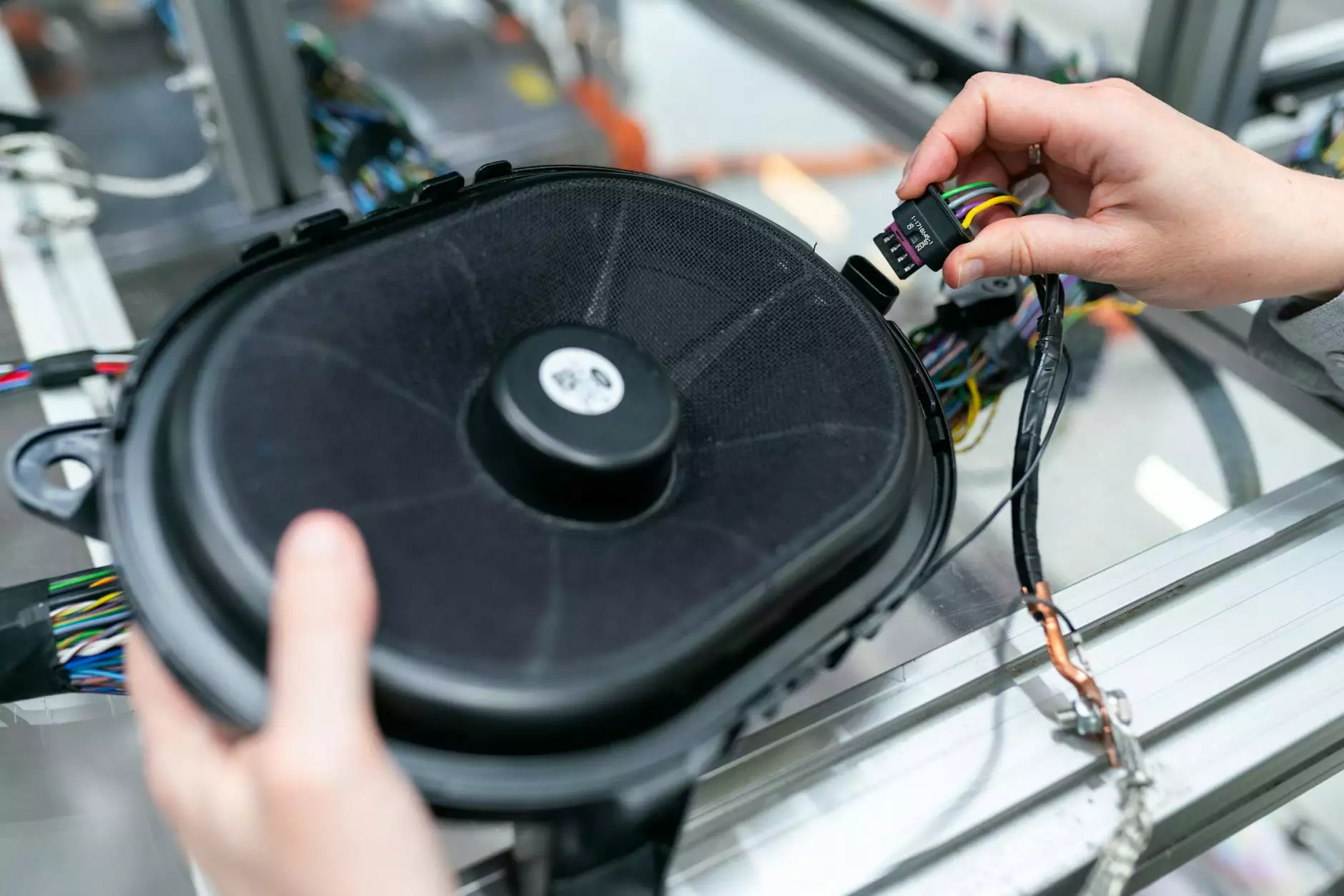

1. Automotive Industry

The automotive sector frequently employs this technique for manufacturing components such as dashboards, interior trims, and even certain engine parts, ensuring high performance and durability.

2. Medical Devices

High-precision components are critical in the medical field. Products such as syringes, implantable devices, and diagnostic tools benefit greatly from the precise nature of injection molding.

3. Consumer Goods

Everyday items such as containers, appliances, and toys are produced using precision injection molding, providing both functionality and aesthetic appeal.

4. Electronics

With the rapid advancement of technology, electronic devices have become more compact, which requires precision parts in their assembly. Injection molding plays a crucial role in producing housings, connectors, and other electronic components.

Challenges in Precision Injection Molding

Despite its many advantages, precision injection molding is not without challenges:

- Upfront Costs: The initial investment for designing and creating molds can be significant, making it less attractive for low-volume production runs.

- Material Limitations: Not all materials can be injected, and some may require special handling or temperature control.

- Complex Setup: Setting up the machinery and molds can be time-consuming, necessitating skilled technicians and engineers.

Innovation in Precision Injection Molding

The landscape of manufacturing is constantly evolving, and precision injection molding is no exception. Recent innovations include:

Advanced Materials

New materials are being developed that enhance strength, flexibility, and thermal resistance, making components produced via injection molding even more durable and effective.

3D Printing Integration

With the rise of 3D printing technology, there is an exciting crossover wherein 3D-printed molds can be used to expedite the molding process, reducing turnaround time for prototypes and production parts.

Automation and IoT

Automation technology, coupled with IoT (Internet of Things) devices, is enhancing the efficiency of injection molding processes, allowing for real-time monitoring and adjustments to optimize production quality.

Conclusion

In conclusion, precision injection molding stands out as a fundamental manufacturing technique that offers a multitude of advantages for businesses, particularly in the metal fabricator sector. With its impressive ability to produce high-quality, precise components efficiently, it has become the go-to solution for many industries. As innovation continues to drive the field forward, those who invest in this technology will likely find themselves at a significant advantage, capable of meeting the ever-evolving demands of their customers and the market.

If you're looking to enhance your manufacturing capabilities and ensure that you remain competitive in a challenging marketplace, consider leveraging the power of precision injection molding. By partnering with a reputable firm like DeepMould.net, you can access the latest advancements in the field and propel your business to new heights.